If you’re ready to infuse new life into your loyal lawn mower, you’ve landed in just the right spot. With an extensive gardening background spanning decades, I’m here to be your trusted companion on the journey of cleaning your lawn mower’s carburetor.

Your mower’s carburetor, often the unsung hero, plays a pivotal role in the engine’s performance. Ensuring it’s clean and well-maintained is paramount to achieving a flourishing lawn and extending the life of your beloved machine. Allow me to guide you with my professional insights, and together, we’ll have your mower humming like a well-oiled machine in no time.

Tools and materials needed for cleaning the carburetor

To effectively clean the carburetor in a lawn mower, it is essential to have the right tools and materials at hand. A high-quality carburetor cleaner is a must-have for this task. Look for a cleaner that is specifically designed for carburetors and can effectively remove dirt, grime, and varnish buildup.

Additionally, a set of precision screwdrivers is necessary to disassemble the carburetor and clean its various components. Ensure the screwdrivers are the correct size to avoid damaging the delicate parts. A small wire brush is also vital for scrubbing away any stubborn debris, and a can of compressed air can help blow out any residual dirt from hard-to-reach areas.

Finally, having clean, lint-free cloths or paper towels on hand will aid in the overall cleaning process.

In order to tackle the task of cleaning a carburetor in a lawn mower, a few additional tools may be needed. It is beneficial to have a small container or bowl to hold the carburetor and its components during the cleaning process. This will make it easier to keep track of the various parts and prevent them from getting lost or damaged.

Depending on the specific make and model of the lawn mower, a fuel line clamp may be necessary to stop the flow of fuel before removing the carburetor. Additionally, having a pair of latex gloves is recommended to protect your hands from any chemicals or grime that may be present during the cleaning process. These tools and materials are essential for a successful and thorough carburetor cleaning job.• A high-quality carburetor cleaner specifically designed for carburetors

| Tools and Equipment |

|---|

| Precision screwdrivers of the correct size to avoid damaging delicate parts |

| Small wire brush for scrubbing away stubborn debris |

| Can of compressed air to blow out residual dirt from hard-to-reach areas |

| Clean, lint-free cloths or paper towels for overall cleaning process |

| Small container or bowl to hold carburetor and its components during the cleaning process |

| Fuel line clamp (depending on specific make and model of lawn mower) to stop fuel flow before removing the carburetor |

| Pair of latex gloves to protect hands from chemicals or grime present during the cleaning process |

Step 1: Disconnect the spark plug

Before beginning the process of cleaning your carburetor, it is crucial to take the necessary safety precautions.

One of the first steps is to disconnect the spark plug – some engines may have more than one spark plug, so be sure to disconnect all spark plug wires. The spark plug is responsible for igniting the fuel mixture in the combustion chamber of an engine. By disconnecting the spark plug, you minimize the risk of the engine starting accidentally while you are working on the carburetor. This not only protects your safety but also prevents any potential damage to the carburetor or other engine components. Make sure to use an appropriate-sized socket wrench to carefully remove the spark plug wire.

Once the spark plug is disconnected, it is essential to secure the wire properly to prevent any accidental reconnection. This can be done by placing the disconnected spark plug wire away from the spark plug itself, ensuring it does not touch any metal parts of the engine. By doing so, you eliminate the risk of electrical shock and avoid damaging any sensitive electrical components. Remember, taking these precautions and handling the spark plug with care is a fundamental step in the carburetor cleaning process, ensuring a smooth and safe procedure.

Step 2: Locate the carburetor

Locating the carburetor is an essential step in the process of cleaning it. To begin, ensure that you have ample lighting and a clear workspace to prevent any accidental damage. Start by examining the engine and following the fuel line. Typically, the carburetor is situated near the air filter or on the side of the engine. Check your engine’s manual for precise instructions if you are uncertain about its location.

Once you have located the carburetor, it is important to familiarize yourself with its components, as this will facilitate the cleaning process. A carburetor is a complex mechanism that mixes fuel and air to provide the engine with the correct fuel-to-air ratio. The key parts you need to identify include the choke and throttle plates, float bowl, jets, and needle valve. Each of these components plays a vital role in the carburetor’s functionality, and understanding their location will facilitate a successful cleaning process. Take note of their positions and connections for later reassembly.

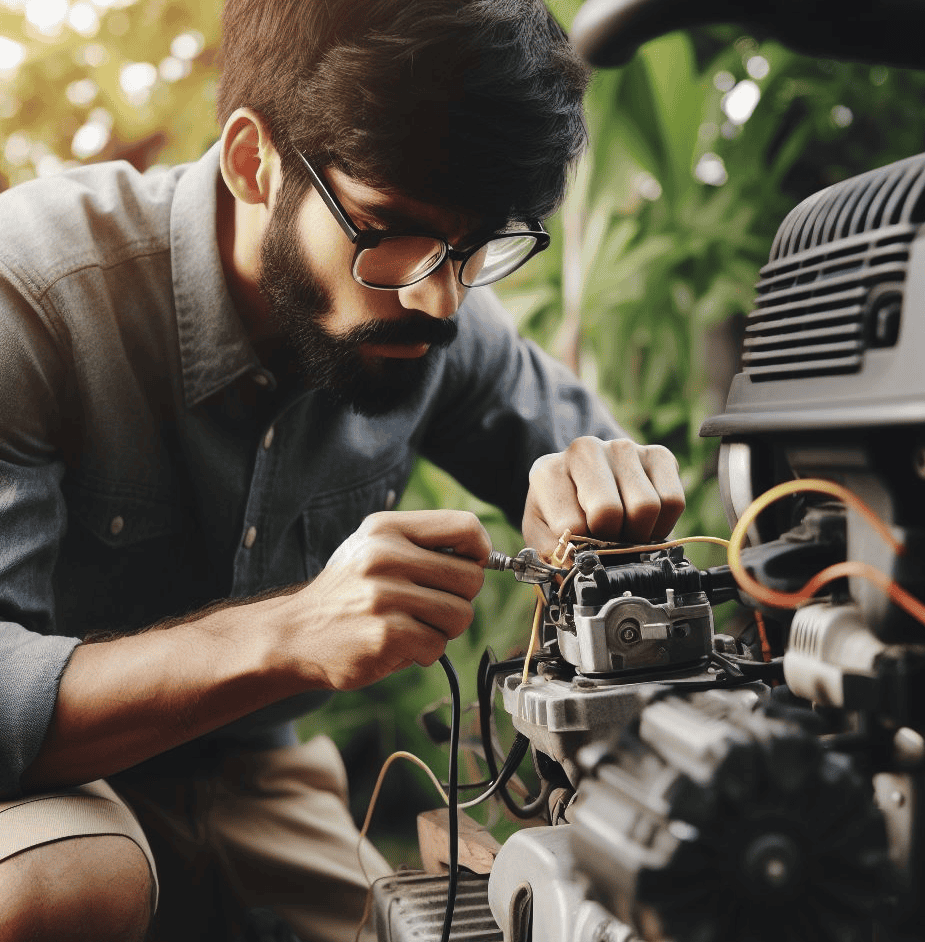

Step 3: Remove the carburetor

To begin the process of removing the carburetor, you need to make sure you have all the necessary tools and materials at hand. These include a screwdriver, pliers, a socket set, and possibly some gasket sealant. It’s important to have the right tools to ensure a smooth and efficient removal process. Additionally, you should have a clean and well-lit workspace to work in.

Note: be sure to drain the fuel first before fully removing the carburetor, to avoid spilling fuel

Once you have gathered all the necessary tools, the next step is to locate the carburetor in your engine. It is typically located on the top or side of the engine, depending on the make and model of your vehicle. You may need to refer to your vehicle’s manual to accurately locate the carburetor. Once you have identified its position, you can proceed to remove it. This may involve disconnecting various hoses and electrical connections, so it is crucial to pay attention to the details and keep track of each step to ensure a successful removal.

Step 4: Disassemble the carburetor

Disassembling the carburetor requires careful attention to detail and a methodical approach. Begin by removing any external components, such as the air filter or fuel lines, that are attached to the carburetor. Take note of the arrangement and order of these components to ensure proper reassembly later on. Once all external components are detached, use a carburetor cleaning spray to thoroughly clean the exterior of the carburetor, removing any dirt or debris that may have accumulated.

After cleaning the exterior, it is time to delve into the inner workings of the carburetor. Start by carefully removing the bowl or float chamber, which houses the fuel filter and fuel inlet valve. Take note of the positioning and orientation of the bowl to easily reassemble it later. Next, detach the throttle plate and choke plate, being cautious not to damage any delicate components. These plates control the flow of air and fuel into the engine and may require careful maneuvering to remove smoothly. Once all of these components have been successfully disassembled, proceed to the next step: cleaning the carburetor components to ensure optimal performance.

Step 5: Clean the carburetor components

To effectively clean the carburetor components, start by carefully inspecting each part for any signs of damage or excessive wear. Look for clogged or dirty fuel jets, as these can significantly affect the carburetor’s performance. Carefully remove the fuel bowl and clean it thoroughly using a carburetor cleaner solution. Make sure to remove any dirt or debris that may have accumulated inside the bowl.

Next, examine the carburetor’s float and needle valve assembly. It is essential to inspect these components for any signs of wear or damage, as they play a crucial role in regulating the fuel flow. Gently clean the float and needle valve using a soft-bristled brush and carburetor cleaner. Take extra care not to damage or bend the float, as this can cause fuel overflow and affect engine operation. Additionally, inspect the gasket or O-ring seals and replace them if necessary to ensure proper sealing and prevent fuel leaks.

Note: Jets should be cleaned with compressed air versus brushes to avoid damage. Gentle cleaning of delicate parts is a must.

Step 6: Reassemble the carburetor

After successfully cleaning the various components of the carburetor, it is now time to reassemble the carburetor. Begin by carefully inspecting each part to ensure that they are clean and free from any debris. Take note of the gaskets and seals, making sure they are not damaged or worn out. If any components are damaged, it is recommended to replace them with new ones to ensure optimal performance of the carburetor.

Next, refer to the carburetor diagram or manual to guide you in the correct placement of each component. Start by placing the fuel bowl back onto the carburetor body, ensuring that it is securely fastened with the screws or bolts. Carefully reattach the float assembly, taking note of its proper orientation. Attach the needle valve and seat, making sure they are aligned properly. Finally, reinstall any other parts that were removed during the disassembly process, ensuring that they are securely in place.

Reassembling the carburetor requires precision and attention to detail. Following the manufacturer’s instructions and guidelines is crucial to ensure a successful reassembly. Taking your time and double-checking each step will minimize the chances of errors or omissions. By reassembling the carburetor correctly, you can ensure its proper functioning and optimize the performance of your equipment.

It is also highly recommended to replace any gaskets/seals for optimal sealing.

Step 7: Reinstall the carburetor

After thoroughly cleaning the carburetor components, it is time to proceed with the reinstallation process. Begin by carefully placing the carburetor back into its original position. Ensure that all the connections align correctly and securely fasten them in place using the appropriate screws or bolts. Take note of the carburetor gasket and make sure it is properly positioned before tightening the mounting hardware. This will help prevent any potential air leaks that could affect the engine’s performance.

Always remember to test for fuel leaks once installed before fully reconnecting everything

Next, reconnect the fuel line to the carburetor. Be cautious not to overtighten the fittings, as this could lead to damage. Double-check for any signs of wear or deterioration on the fuel line, and replace it if necessary. Once the fuel line is secured, reattach the throttle linkage and ensure smooth movement without any obstructions. Finally, reconnect any other cables or wires that were disconnected during the removal process, ensuring proper connections are made using the appropriate tools. Taking the time to ensure everything is securely reinstalled is crucial for the proper functioning of the carburetor.

Tips for maintaining a clean carburetor

Keywords: maintenance, cleaning solution, debris, clogged, fuel efficiency, preventive measures.

To ensure the optimal performance of your carburetor and extend its lifespan, regular maintenance is crucial. One key tip for maintaining a clean carburetor is to use a specially formulated cleaning solution. These solutions are designed to effectively dissolve any built-up deposits or grime, allowing for a thorough cleaning. It is important to note that using regular household cleaners or solvents can potentially damage the carburetor, so it is imperative to select a professional-grade cleaning solution.

Another essential tip is to frequently check and clear any debris that may have accumulated in the carburetor. Over time, small particles or dirt can find their way into the carburetor, leading to clogged fuel passages and reduced fuel efficiency. Regularly inspecting and cleaning the air filter, as well as the carburetor’s intake and fuel bowl, can help prevent such issues. Taking these preventive measures will not only maintain a clean carburetor but also contribute to the overall smooth functioning of your engine.

Common Mistakes to Avoid When Cleaning the Carburetor

One common mistake to avoid when cleaning the carburetor is using harsh chemicals or solvents. While it may be tempting to use a strong cleaner to remove stubborn buildup, it can actually cause more harm than good. Harsh chemicals can eat away at the delicate components of the carburetor, leading to damage and potential malfunction.

It is important to use carburetor cleaner specifically designed for this purpose, as it is formulated to effectively remove dirt and residue without causing any damage.

Another mistake to steer clear of is neglecting to properly reassemble the carburetor after cleaning. It is crucial to pay attention to the proper placement of every component and ensure that they are securely fastened together. Failing to properly reassemble the carburetor can result in poor performance, leaks, or even complete failure of the engine.

It is recommended to refer to the manufacturer’s instructions or consult a professional if you are unsure about the correct reassembly process. Taking the time to double-check your work and ensure everything is in its proper place will help prevent any issues down the line.

FAQ

What tools and materials do I need for cleaning the carburetor?

To clean the carburetor, you will need a set of screwdrivers, carburetor cleaner solution, a brush with stiff bristles, compressed air, safety goggles, and gloves for protection.

How do I disconnect the spark plug before cleaning the carburetor?

To disconnect the spark plug, start by locating it on the engine. Once located, carefully remove the spark plug wire by firmly pulling it straight off the spark plug. This ensures no accidental ignition during the cleaning process.

Where can I find the carburetor on my engine?

The carburetor is usually located near the engine’s air filter or intake manifold. Refer to your engine’s manual or online resources specific to your engine model for accurate information on carburetor location.

How do I remove the carburetor?

Before removing the carburetor, ensure that the fuel supply is disconnected. Depending on your engine model, there may be screws or bolts securing the carburetor. Use the appropriate tools to carefully remove them, then gently disconnect any linkage or vacuum lines before lifting the carburetor off.

How do I disassemble the carburetor for cleaning?

Disassembling the carburetor involves removing the screws or bolts that hold the various components together. Take pictures or make notes of the carburetor’s original configuration to aid in reassembly. Ensure a clean and organized workspace to avoid misplacing any small parts.

How should I clean the carburetor components?

Use a carburetor cleaner solution and a brush with stiff bristles to clean the components. Gently scrub away any accumulated dirt, grime, or varnish, paying close attention to the small passages and jets. Utilize compressed air to blow out any remaining debris.

How do I reassemble the carburetor after cleaning?

Refer to the pictures or notes taken during disassembly to ensure proper reassembly. Carefully reattach all components, screws, and bolts, making sure they are securely tightened. Follow the reverse order of disassembly steps.

How do I reinstall the carburetor onto my engine?

Align the carburetor properly with the mounting studs or bolts on the engine, then gently slide it into place. Reattach any linkage or vacuum lines that were disconnected earlier. Secure the carburetor with the appropriate screws or bolts, ensuring a snug fit.

What tips can you provide for maintaining a clean carburetor?

Regularly inspect and clean the carburetor to prevent clogging. Use high-quality fuel and add fuel stabilizers if the engine will be sitting idle for extended periods. Follow the manufacturer’s recommendations for maintenance intervals and procedures.

What common mistakes should I avoid when cleaning the carburetor?

It is important to avoid using excessive force when disassembling or reassembling the carburetor, as it may damage delicate components. Additionally, ensure that all parts are thoroughly cleaned and properly reassembled to avoid any performance issues. Taking proper safety precautions, such as wearing gloves and safety goggles, is also crucial.

Michael Miller is a gardening enthusiast with a green thumb and a knack for fixing anything related to the world of plants. He envisions owning a vineyard in the future, a testament to his deep love for cultivation. Happily married with two kids in vibrant Tokyo, Japan, Michael’s life is a blend of botanical beauty and family bonds. Join him on his journey where gardening passion meets a vision for the future, and explore the secrets of cultivating a harmonious life.